Fatal 6 – Operator hit by moving rail mounted machinery

LOCATION:

CONCRETE PRODUCTS PLANT

ACTIVITY:

PRODUCTION AND PROCESSING

SUB ACTIVITY:

CONCRETE PRODUCTS

DATE ISSUED:

09/01/2019 16:47:39

TITLE

Fatal 6 – Operator hit by moving rail mounted machinery

COUNTRY OF ORIGIN

WHAT HAPPENED

On the 5th June 2014 a precast concrete plant worker received fatal head injuries when caught between two rail mounted machines used in the production of concrete goods. The deceased was operating an automatic sawing machine on a prestressing line when it was passed by a machine laying out the wires on the adjacent track. The deceased was standing on a working platform on the stationary sawing machine while the other machine passed. The gap between the two passing machines was approximately 65mm. The deceased appears to have lent forward into the path of the oncoming machine resulting in fatal crush/shear head injuries.

This fatal accident in 2014 is still under investigation by HSE.

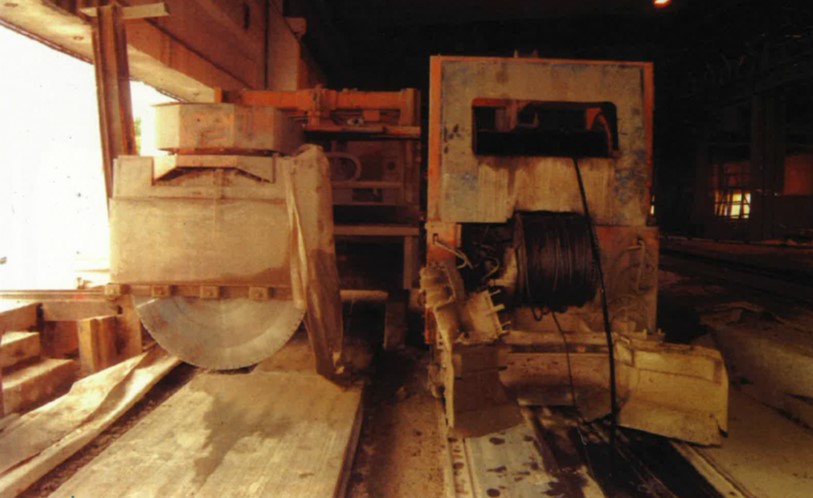

The photograph below shows the saw machine on the left and the wire laying machine on the right. The very small gap between the two passing machines can clearly be seen.

ACCIDENT / INCIDENT IMAGES

Click image to enlarge

LEARNING POINTS / ACTIONS TAKEN

• British standards, including BS EN 349, provide minimum gaps to avoid crushing parts of the human body and additional information to assist reviews of machinery placement.

• Check that there is sufficient clearance between rail mounted machinery and other machinery and obstructions which may be present (particularly on end rails).

• Check that a suitable and sufficient risk assessment of machinery operation has been carried out for multi-line stressing systems.

Check that suitable control measures are in place to deal with any risk from machines passing on adjacent lines

LEARNING POINTS / ACTIONS IMAGES

LOCATION:

CONCRETE PRODUCTS PLANT

ACTIVITY:

PRODUCTION AND PROCESSING

SUB ACTIVITY:

CONCRETE PRODUCTS

DATE ISSUED:

09/01/2019 16:47:39

Go Back to Search Critera