A contractor carrying out a quarry earthmoving campaign was required to cease operations and was expelled from the site on grounds of unsafe practices.

This action was taken because the following issues were identified:

- Non-compliance with the company’s PPE policy – identified during VFL visit and subsequently not acted upon.

- Lack of notification to relevant Quarry Responsible Manager when accessing site.

- Failure to stockpile mineral as per design document, including:

- Ensuring correct material compaction (to minimise geotechnical instability).

- Excessive height of stockpile.

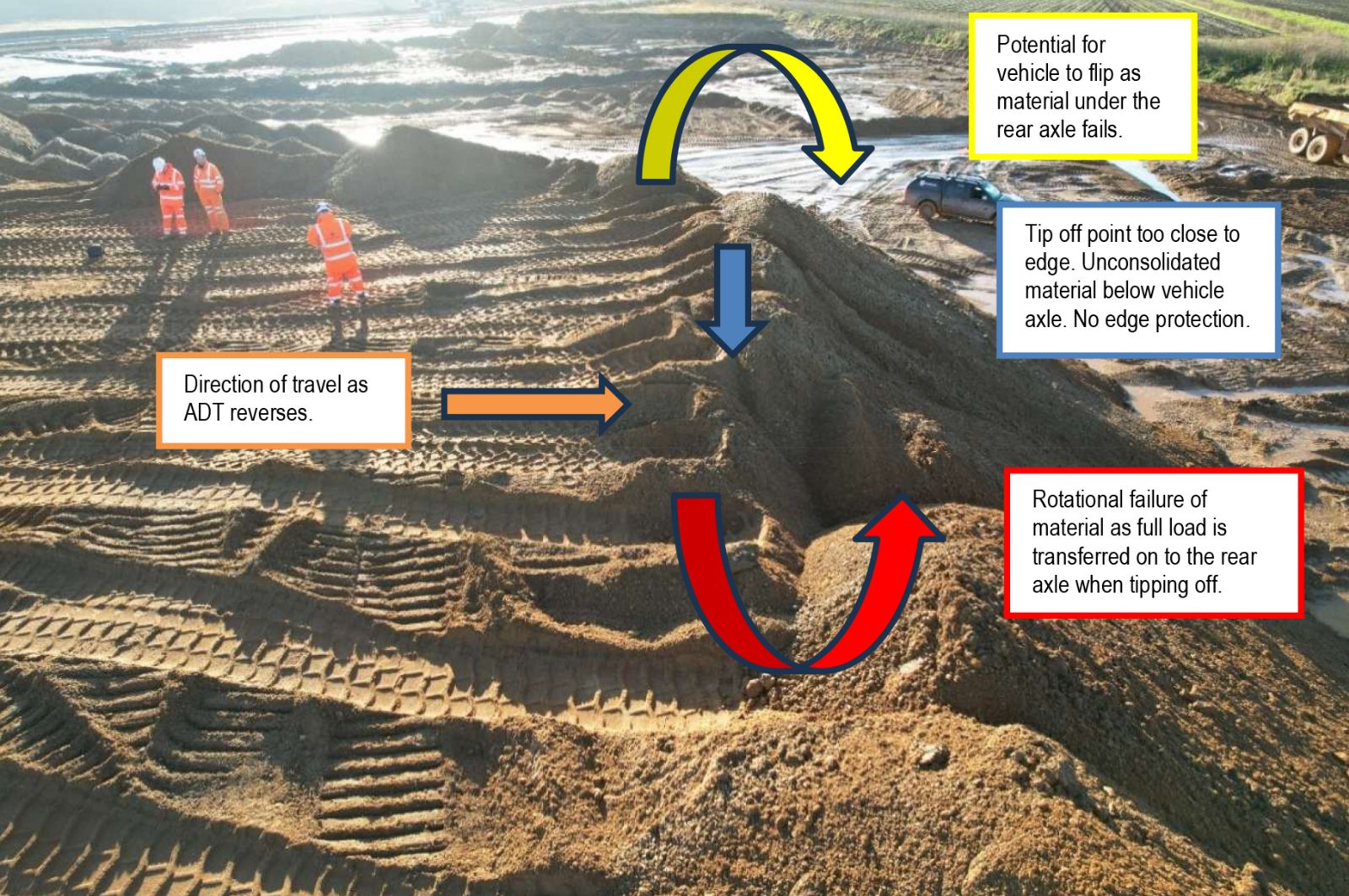

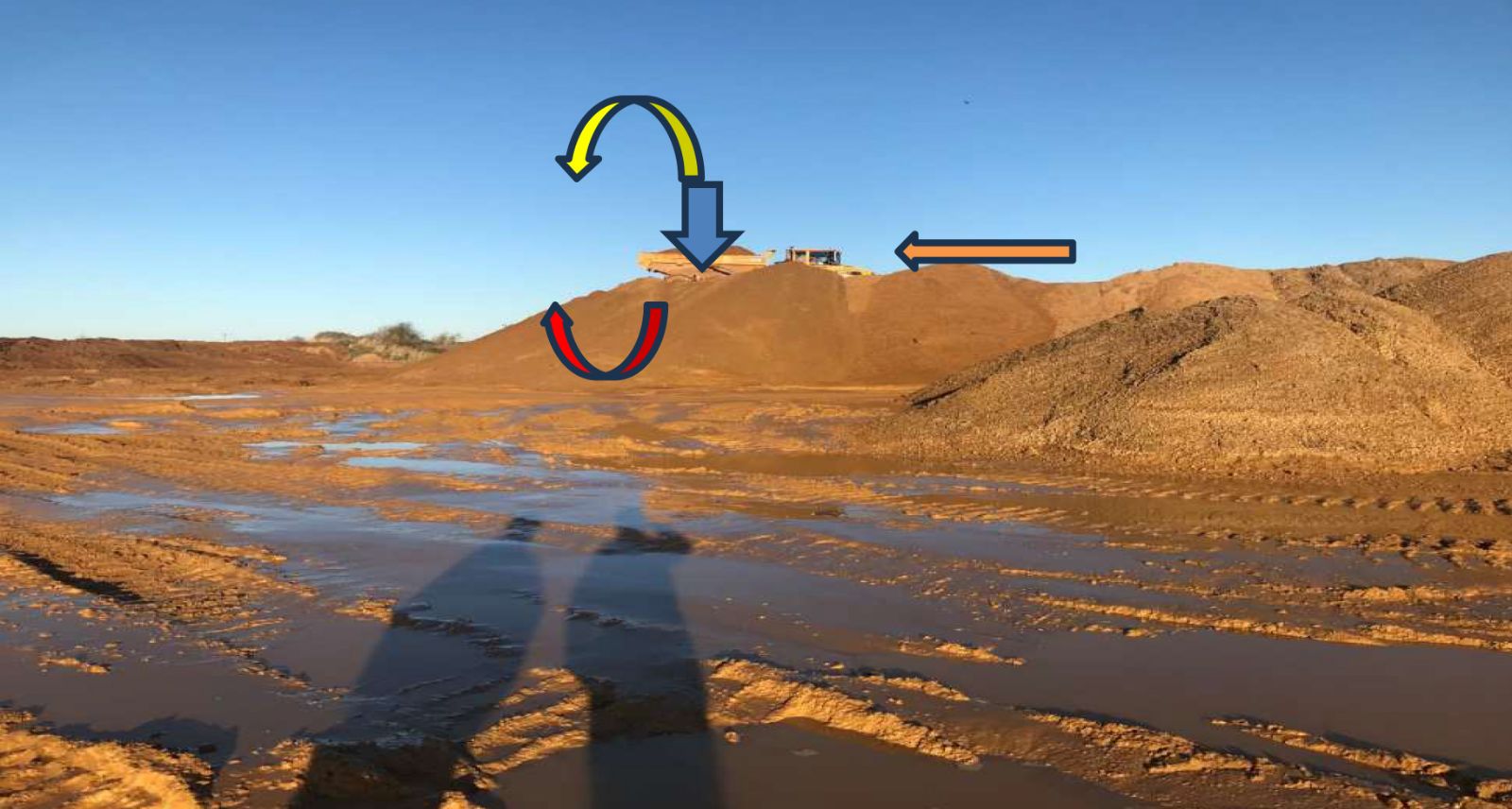

- High risk end tipping activities. End tipping is forbidden on all the company sites.

- Missing edge protection

- Inaction following previous improvement request.

The contractor had been warned on several occasions that they weren’t operating to the design specification and standards the company required and had not carried out the improvements issued by the site’s appointed responsible managers.

Details of the occurrence are found below to provide further insight into this example.

END TIPPING

View from above the stockpiled material Side view of the stockpiled mineral

The edge protection

Please see below an example of end tipping that occurred in the USA. This incident resulted in a fatality.

Link to accident report: https://www.msha.gov/data-reports/fatality-reports/2023/may-22-2023-fatality/final-report