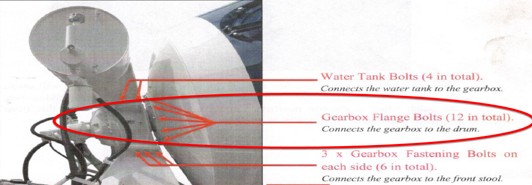

A truck mixer was being loaded with 4m3 of concrete, the first load of the day. Upon noticing a metal-on-metal noise, the driver moved away from the loading bay to investigate the issue. He discovered several of the bolts securing the gearbox and drum had sheared, leaving only three bolts holding the drum in place, see the image below. A new gearbox had been fitted less than 18 months previously.

On inspecting the remaining bolts in the flange, one was identified as a high-tensile grade 10.9 bolt which is the correct bolt for mounting the gearbox & flange to the drum, while the other was a grade 8.8 bolt, more usually found on mounting brackets that allow for movement. This high potential (HiPo) incident could have had catastrophic consequences if the drum had become detached.

KEY FINDINGS

Safe Systems

- A Safequarry alert, which was issued in January 2025, covered a very similar incident where a mixer drum could have easily become detached due to a maintenance failure. This had been shared with both the owner and driver of the vehicle involved in this incident. However, it appears regular maintenance inspections were not undertaken as recommended in this earlier alert. Follow this link to see previous alert.

- In 2023, there was another incident on highway where a mixer drum did become detached due to a structural failure in the chassis. See incident.

Inspection and maintenance

- The truck owner’s incorrect maintenance decisions highlight the need for better understanding of potential consequences of poor decisions and inspection regimes.

- Truckmixer drivers should visually inspect the mixer gearbox mounting bolts (see the image below) as part of their daily pre-use inspection, checking for signs of movement or missing bolts.

Tools and equipment

This type of incident appears more likely to occur following the removal of the drum or installation of a new gear box.