| Establishing the GAP - proactive emergency scenario analysis |

Description

From the implementation of the Construction Design & Management Regulations (CDM) there has been a requirement for documented Risk Assessment and Method Statements, produced to ensure that all site operations are completed safely to a known method that minimises risk and ensures the safest method of undertaking a given task.

To uncover any weaknesses, random emergency scenarios were undertaken on sites across the country to expose the good and bad within the company’s systems and people. The overall aim of the exercise was to promote a true understanding of where the company is and the GAP between there and where it should be.

In the emergency scenarios, a number of site operatives (subcontractors included) were classed as ‘dead’ as a result of ‘Incident X’. The site team was instructed to act as they would in a real situation., with a senior manager/director appointed to investigate in the manner of the police or an HSE officer.

Such drills are used as an opportunity to measure the resilience of the company’s procedures under scrutiny. From the findings, GAP analysis identifies the true situation.

This internal exposure produced an ‘awakening’ that for many is only experienced when they are involved with a real accident. To overcome the GAP established from the results, leadership programmes and training initiatives have followed and extensive rounds of emergency drills are planned to ensure continuous improvement throughout 2010.

Benefits

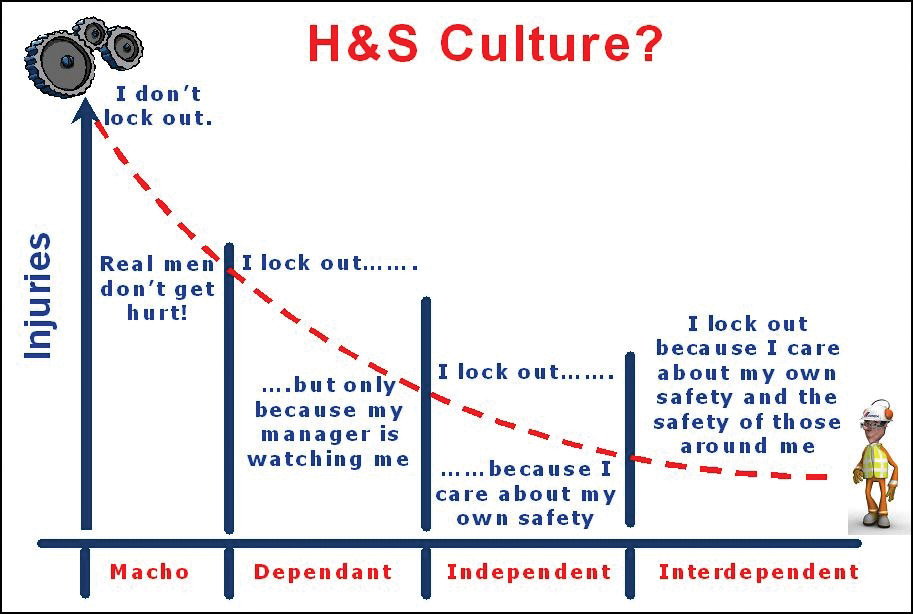

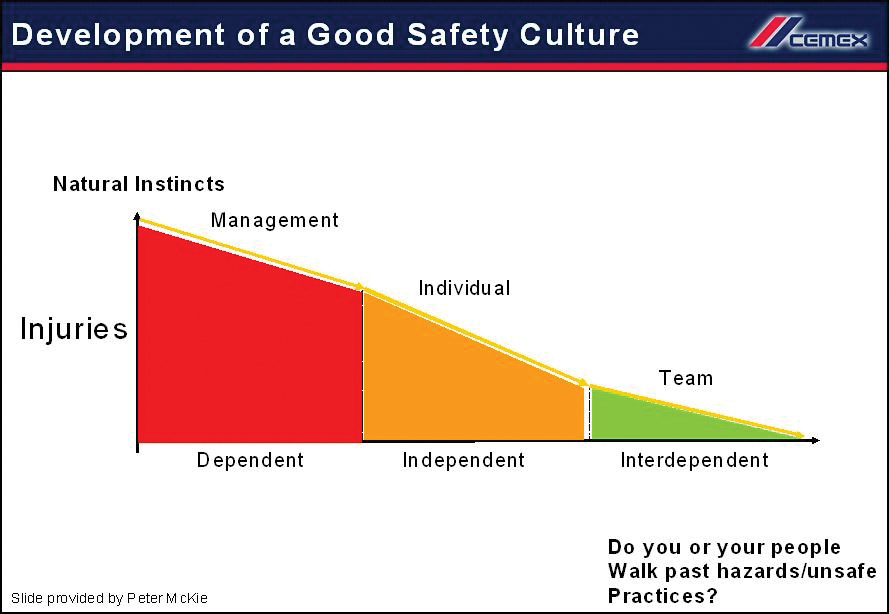

The site culture is changing. Site management and their teams are challenging senior manager(s) to visit them and find fault. This is driven from a belief that the site team is not only acting correctly, but also has a desire to find that “hidden issue” and therefore improve safety even further. The net result is a team commitment to safer working.

|

Click image to enlarge

|

Click image to enlarge

|

|