| Auto locking saw guards – Engineering Winner |

DESCRIPTION

Bridge saws are notoriously difficult to guard, often they are installed in tight spaces surrounded by pallets of work in progress and constant fork truck activity. Conventional folding gates, even bifold, swing far too large an arc to be operated in such an environment. The requirement for crane access combined with limited space and saw debris on the floor prevent the use of tracks either above or below the gate thus preventing the erection of conventional concertina or sliding gates. Electronic light beam guards are expensive and impractical for this environment.

Marshall’s Stancliffe Stone plant used a simple chain stretched across the opening. This offered little protection to workers should they fall, trip or simply decide to ignore it.

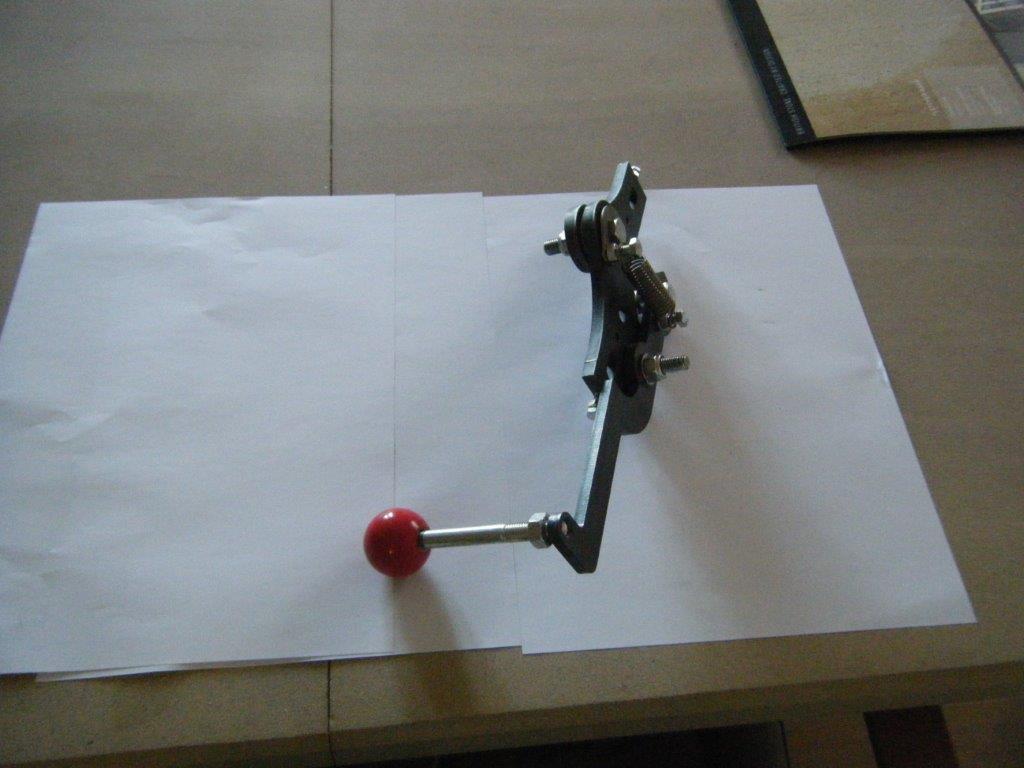

It was recognised that a concertina style guard with multiple folding gates would be a good solution but in this application every fold of the gate would need to be rigidly locked. For practical use it would need to be rigid, self locking, multiple folding guards that were simple and inexpensive to manufacture.

As this was not available from existing suppliers, Marshalls decided to design and develop this themselves. The machine operators were consulted and a format of 8 pivoting and 2 fixed sections was agreed. This was installed to establish that the system would work. A new locking system was then developed that ensured that the guarding could be easily opened and closed but would be rigid once closed.

BENEFITS

• Inclusive process of design, development and testing

• A reliable and effective guarding system now in place

• System can be easily adapted to other difficult guarding environments

• Ideal for saw sheds, bridge saws and other equipment in confined space

• Guarding system now being deployed at 11 other sites

• A safer and more efficient working environment.

|

Click image to enlarge

New guarding

|

Click image to enlarge

New self locking rigid hinge device

|

|