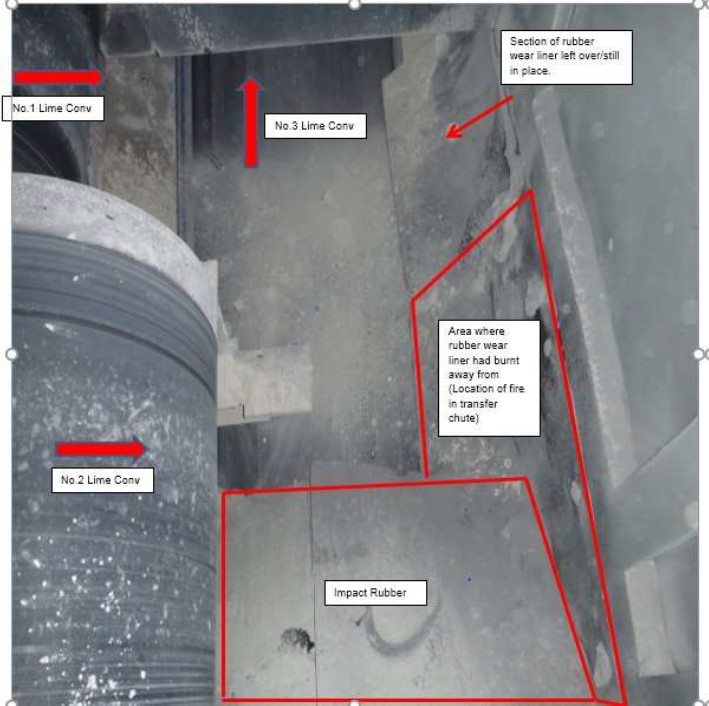

A small fire occurred in a transfer chute between lime discharge conveyors in the shaft kilns basement. The fire was detected by an employee who raised the alarm. The site team responded and used fire extinguishers and a fire hose to extinguish the fire. The damage was limited to the rubber wear liner in the chute but no further impact to the plant.

Investigation Detail:

- Rubber liners made from heat resistant conveyor belt rubber were in place in the transfer chute.

- Over time the resistant rubber had worn exposing the core fibres of the liner and creating a hole in which lime could build up.

- Hot lime (~200c) became lodged in the hole in the liner and began to smoulder before breaking into flames and burning the rubber liner.

- The site team followed the emergency response plan and dealt with the fire quickly preventing further impact.

- The fire service attended the scene and assisted with extinguishing the fire and fire watching.

- The shaft kilns were running to normal operating conditions and no abnormally hot lime was detected by the thermal cameras on the conveyor belts before the transfer chute.

- The liner was on a 12-month replacement schedule but had worn more quickly due to additional kilns being online producing more product therefore increasing wear.