Insurance Inspector Near Miss

ACTIVITY:

MAINTENANCE & HOUSEKEEPING

TITLE

Insurance Inspector Near Miss

COUNTRY OF ORIGIN

WHAT HAPPENED

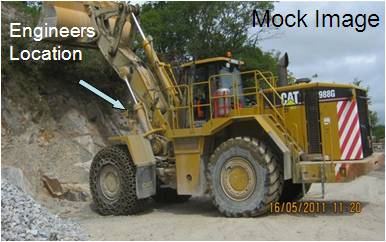

An insurance engineer was undertaking statutory inspections on a number of items of mobile plant at a UK Quarry. During the engineer’s inspection of a CAT 998g loading shovel, the engineer was seen to be accessing the front of the Front End Loader (FEL) between the axles beneath a raised boom and bucket.

The unit manager was on site tour at the time and as soon as he observed this unsafe act he stopped the activity and requested the engineer moved away from the plant to a safe location where the unit manager outlined the dangers that the engineer had exposed himself to.

It was established that the loading shovel was switched off but the driver was still in the cab with the keys in the ignition. The plant operator had dropped the dead man switches to prevent movement of the stick controls, however he confirmed that he did not anticipate the engineer climbing on to the front of the FEL underneath the raised bucket.

When Questioned the FEL operator claims that the engineer could not be seen when he climbed on the front of the loader and eventually off over the wheel arch and front tyre.

ACCIDENT / INCIDENT IMAGES

Click image to enlarge

LEARNING POINTS / ACTIONS TAKEN

A full investigation and panel of inquiry has been conducted which has forwarded the following provisional conclusions:

- The Risk Assessment (RA) and Safe Working Practice (SWP) provided by the insurance company was not suitable & sufficient.

- The Quarry responsible manager did not effectively review the RA & SWP prior to issuing permission to proceed.

- The insurance engineer did not recognise the potential hazard of crushing / entrapment.

- The FEL operator was not fully briefed on the inspection method.

- The insurance company have a dynamic point of risk assessment tool, but the engineer was not aware of its existence and had not been trained in its use.

Always ensure that all task risk assessments manage all reasonably foreseeable hazards and the controls implemented are suitable and sufficient prior to issuing permission to proceed.

(Editors note: Similar incidents have occurred within the industry; where an insurance inspector exposed themselves to risk when undertaking a cable inspection and when a specialist engineer suffered injuries when using a hydraulic bolt tensioner. The lesson is that specialists can’t just be left to get on with the job, the normal rules of ensuring that risk assessments and their associated controls address reasonably foreseeable hazards and ensuring that they are actually followed, still apply!)

LEARNING POINTS / ACTIONS IMAGES

ACTIVITY:

MAINTENANCE & HOUSEKEEPING

Go Back to Search Critera