Angle Grinder Kick Back

ACTIVITY:

MAINTENANCE & HOUSEKEEPING

TITLE

Angle Grinder Kick Back

COUNTRY OF ORIGIN

WHAT HAPPENED

An experienced operator was using a 9 inch angle grinder to cut out lower stainless steel welding fillets in the clinker cooler.

As the operator approached the cooler wall he couldn’t operate the grinder vertically, so moved to position where he was using it by holding the grinder horizontally. In order to access the last two welds he remained standing but stooped in order to hold the angle grinder in a more horizontal plane as the previously steeply inclined position could not be accommodated so close to the cooler wall.

During the use of the grinder horizontally, the blade snagged in the steel being cut and kicked back towards the user. As the grinder kicked back the rotating blade caught his left thigh, resulting in a laceration about 60mm in length and 25mm deep, that required immediate first aid and hospital treatment.

ACCIDENT / INCIDENT IMAGES

Click image to enlarge

Fillet Being Cut

Fillet Being Cut

Click image to enlarge

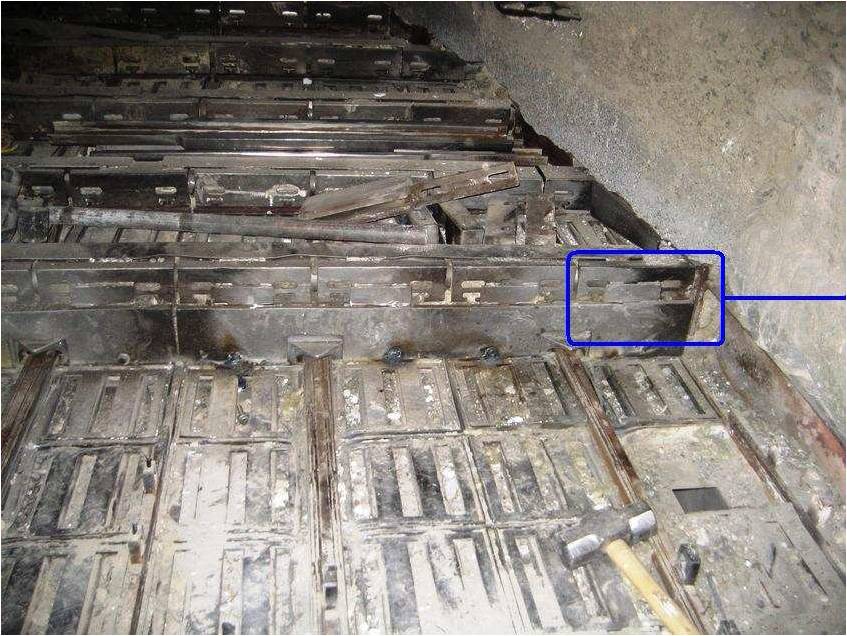

Cut Out of Alignment

Cut Out of Alignment

LEARNING POINTS / ACTIONS TAKEN

The operator had considered the options available to him for the cutting operation, which included gouging, the use of 4½ or 9 inch angle grinder.

The use of gouging was ruled out as no welder was available, and the stainless welds would give rise to significant fume requiring the use of an extraction system.

He requested a 4½ inch angle grinder in the belief that they are easier to handle and control: and this was requested from store. Unfortunately of the 16 stocked before the shutdown not one was available. As an alternative, a 9 inch angle grinder was issued for use.

There was insufficient space available close to the cooler wall to allow the 9 inch angle grinder to be used in a near vertical position where a consistent even cut through the stainless steel welds was possible. Therefore the machine was used in a more horizontal plane which resulted in an off-horizontal cut, that in turn resulted in the blade snagging and kicking back.

On investigation it was found that a similar incident with a 9 inch angle grinder had occurred on another industry site and that other incidents, including a disc failure had also occurred historically.

The use of 9 inch angle grinders was suspended until a full evaluation of the need to use this type of equipment has been made (and further 4½ inch angle grinders were sourced).

Subsequently if there is a call for the use of a 9 inch angle grinder, then a task specific risk assessment must be completed: and the 9 inch angle grinder will only be permitted for the use of that operation only.

Following the incident all contractors were stood down and briefed.

LEARNING POINTS / ACTIONS IMAGES

Click image to enlarge

Cutting Position

Cutting Position

ACTIVITY:

MAINTENANCE & HOUSEKEEPING

Click image to enlarge

Recovered Grinder

Recovered Grinder

Go Back to Search Critera